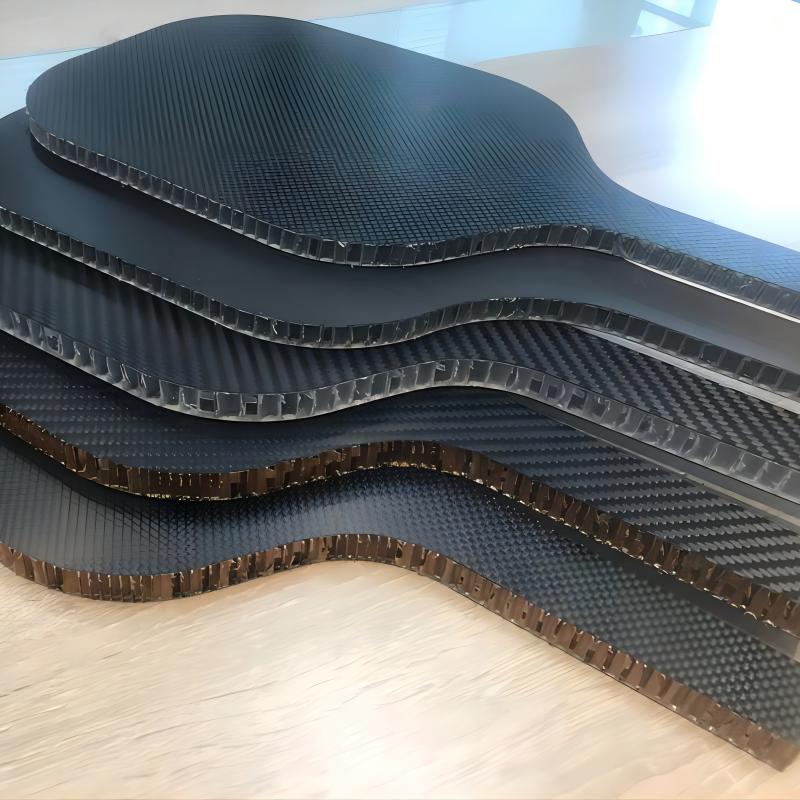

Typical application scenarios of composite materials in the field of sports equipment

Composite materials (such as carbon fiber reinforced composites, glass fiber reinforced polymers, etc.) are widely used in the field of sports equipment due to their advantages of lightweight, high strength and designability. The following are some typical application scenarios and specific cases:

1. Golf club application parts: club body, club head.

Material advantage: The carbon fiber rod body is 30%~50% lighter than the traditional steel rod, improving the swing speed and control. The high rigidity reduces the energy consumption of the shot and increases the distance of the shot.

2. Bicycle application parts: frame, wheel set, front fork.

Material advantages: The carbon fiber frame weighs only about 1kg (steel frame about 3kg), while maintaining high rigidity and shock absorption. Fiber layering direction can be customized to optimize the strength of different parts (such as five-way rigidity, rear fork shock absorption).

3. Tennis racket application parts: racket frame, racket handle.

Material advantage: Carbon fiber + epoxy frame provides high torsional rigidity and reduces batting vibration. Light weight (about 250~300g), suitable for fast swing.

4. Snowboard and pole application parts: board core, board surface, pole body.

Material advantage: Carbon fiber + glass fiber hybrid structure improves elasticity and impact resistance. Reduce weight (the carbon fiber pole body is 20% lighter than aluminum) and facilitate high-speed coasting.

5. Fishing rod application parts: rod body, guide ring support.

Material advantage: The carbon fiber rod body is light and sensitive, and can sense subtle fish signals. High modulus carbon fiber provides high strength and is suitable for sea fishing large fish.

6. Application parts of badminton racket: racket frame, middle pole.

Material advantage: Carbon fiber frame light weight (about 80~90g), fast swing, kill the ball power. Nano-resin enhances flexural resistance and prolongs service life.

7. Application parts of rowing and paddle board: hull, paddle blade.

Material advantages: The carbon fiber hull is lightweight (40% lighter than the aluminum ship), reducing water resistance. Corrosion resistance suitable for long-term exposure to seawater.

8. Baseball/hockey stick application parts: stick body, hitting part.

Material advantage: The carbon fiber laminated structure improves the batting bounce (10% to 15% more than the batting distance). Better fracture resistance than traditional wood or metal.

9. Application parts of sports protective gear: helmet, knee pads, armor.

Material advantage: Carbon fiber + Kevlar composite provides high impact resistance (such as NFL helmets). Lightweight design reduces exercise burden.

10. Intelligent sports equipment in emerging fields: carbon fiber drone racing frame, e-sports chair skeleton. Disabled sports equipment: lightweight carbon fiber prosthesis, wheelchair frame. The core value of composite material performance improvement: lightweight, high strength, high energy transfer efficiency. Design freedom: Mechanical properties can be optimized through fiber layup design. Durability: fatigue resistance, corrosion resistance, prolong the life of the equipment.

Future trend Mixed materials: carbon fiber + titanium alloy, bio-based resin, etc. 3D printed composite materials: customized sports equipment (such as personalized running shoe midsoles). Sustainability: Recycled carbon fiber for reuse (e.g. bicycle frame recycling technology).

Composite materials are reshaping the performance boundaries of sports equipment, from professional sports to mass sports, and their application will continue to drive innovation in sports performance.

CHINESE

CHINESE New Bright Carbon Fiber Products Co., Ltd

New Bright Carbon Fiber Products Co., Ltd